electrical rough in boxes plug hole Drill holes for cable runs. Pull cable through holes and into boxes. Make up boxes—strip wire ends, splice grounds, splice current-carrying conductors, attach mud rings, and push wires into boxes. Rough-in inspection. After the . There are many alternatives to joining metals. Whether it is for a DIY or a home project, here are our top five ways to weld without a welder. 1.2 Equipment Required for Brazing. 1.3 How to BrazeTwo Metal Pieces. 2.3 How to Solder .

0 · rough in electrical wiring cost

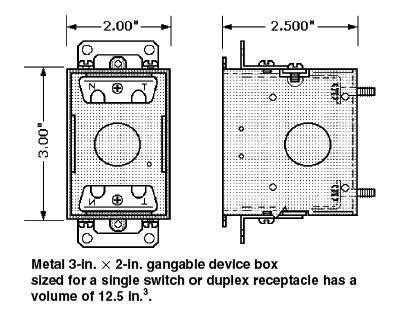

1 · rough in electrical box sizes

2 · rough in box for outside lights

3 · plug in round ceiling box

4 · how to rough in electrical wiring

5 · how to rough in electrical cable

6 · how to rough in electrical box

7 · electrical pipe roughing

In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal .

The exterior plate has a knockout hole with clamps to secure the wires. My new garage door opener has a plug at the end. I got a round single . Cut your hole, mount your box on the block, set your box so it is flush with the angle of the siding and then screw the block into the studs. I .

Starting at the stud holes by one box, push the end of the cable through the holes in the studs until you reach the location of the next box. Cut back about 8 inches of the outer cable sheathing to expose the wiring, but . What is the NEC compliant method for plugging an unused knockout hole where a conduit connector used to be? I see different types - the pop in friction fit, and the mechanical fastener fit with a screw or wing nut. .

Drill holes for cable runs. Pull cable through holes and into boxes. Make up boxes—strip wire ends, splice grounds, splice current-carrying conductors, attach mud rings, and push wires into boxes. Rough-in inspection. After the . If you do not want to reinstall new boxes, you need to plug any holes that are not occupied by electrical cables. Then, be sure you have secured your cables to the stud or some .

Punch a hole (or two for two cables) through the knockout area of the box with a screwdriver or the point on your stripping tool. Push the conductors and about 1/4 inch of sheathed cable into the box and staple the cable within 8 inches of the box. To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at electrical prints and understanding panel and equipment schedules.

The exterior plate has a knockout hole with clamps to secure the wires. My new garage door opener has a plug at the end. I got a round single outlet at my local electrical supply place, but they did not have a faceplate to match the box and outlet.

Cut your hole, mount your box on the block, set your box so it is flush with the angle of the siding and then screw the block into the studs. I prefer the siding blocks because you're only drilling a small hole into the envelope of the house. Starting at the stud holes by one box, push the end of the cable through the holes in the studs until you reach the location of the next box. Cut back about 8 inches of the outer cable sheathing to expose the wiring, but don’t remove the insulation on the inner wires. What is the NEC compliant method for plugging an unused knockout hole where a conduit connector used to be? I see different types - the pop in friction fit, and the mechanical fastener fit with a screw or wing nut. Does the Code call for any particular type?Drill holes for cable runs. Pull cable through holes and into boxes. Make up boxes—strip wire ends, splice grounds, splice current-carrying conductors, attach mud rings, and push wires into boxes. Rough-in inspection. After the inspection, finish surfaces are installed.

If you do not want to reinstall new boxes, you need to plug any holes that are not occupied by electrical cables. Then, be sure you have secured your cables to the stud or some other suitable surface within 8 inches of the box .

chicago electric tool box

rough in electrical wiring cost

When running cable through studs, drill all holes at the same height so that the cable is run level to the floor. Drill holes 6 to 8 in. above or below all switch and receptacle boxes. Do not run No. 14-, 12-, or 10-gauge cable across joists or along the bottom edge of joists. Once the boxes are in place, it’s time to run the electrical wire throughout the framing. Begin by drilling holes in the center of each stud to run the wire through. Keep these holes aligned to make wire pulling easier and neater.

Punch a hole (or two for two cables) through the knockout area of the box with a screwdriver or the point on your stripping tool. Push the conductors and about 1/4 inch of sheathed cable into the box and staple the cable within 8 inches of the box. To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at electrical prints and understanding panel and equipment schedules. The exterior plate has a knockout hole with clamps to secure the wires. My new garage door opener has a plug at the end. I got a round single outlet at my local electrical supply place, but they did not have a faceplate to match the box and outlet.

Cut your hole, mount your box on the block, set your box so it is flush with the angle of the siding and then screw the block into the studs. I prefer the siding blocks because you're only drilling a small hole into the envelope of the house.

Starting at the stud holes by one box, push the end of the cable through the holes in the studs until you reach the location of the next box. Cut back about 8 inches of the outer cable sheathing to expose the wiring, but don’t remove the insulation on the inner wires. What is the NEC compliant method for plugging an unused knockout hole where a conduit connector used to be? I see different types - the pop in friction fit, and the mechanical fastener fit with a screw or wing nut. Does the Code call for any particular type?Drill holes for cable runs. Pull cable through holes and into boxes. Make up boxes—strip wire ends, splice grounds, splice current-carrying conductors, attach mud rings, and push wires into boxes. Rough-in inspection. After the inspection, finish surfaces are installed.

If you do not want to reinstall new boxes, you need to plug any holes that are not occupied by electrical cables. Then, be sure you have secured your cables to the stud or some other suitable surface within 8 inches of the box . When running cable through studs, drill all holes at the same height so that the cable is run level to the floor. Drill holes 6 to 8 in. above or below all switch and receptacle boxes. Do not run No. 14-, 12-, or 10-gauge cable across joists or along the bottom edge of joists.

rough in electrical box sizes

chicago metal fabricators ceo

Well Pump Control Box, Briidea Control Box for 1.5 HP 230 Volt Deep Well Submersible Pump with 6 Preserved Holes, Weatherproof for Outdoor Use

electrical rough in boxes plug hole|electrical pipe roughing